Tube Notching Tool Manufacturers

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer Notching Machine

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Hydraulic Tube Notching Machines.

A tube notching tool is essential for fabricators working with pipes and metal tubes. Built for precise cutting and shaping, it is widely used across automotive, construction, and metal fabrication industries. Whether handling stainless steel, aluminum, or other metals, a reliable tube notcher guarantees accuracy and high performance.

- Provides accurate notching for tubes, pipes, and sheet metal.

- Enhances workflow efficiency while minimizing material waste.

Our sheet metal notching tools make it easier to create clean notches in tubes and metal sheets. With durable construction and user-friendly design, they reduce material waste, improve workflow, and deliver precise results every time.

“Power. Precision. Performance – The HPT Ironworker Promise.”

Hydraulic Notching Machine Features

Tube Notching Precision:

Our tube notching tool offers unmatched accuracy when creating notches in tubes, ensuring proper fit for welding, assembly, and structural projects. Whether you’re working on small-scale jobs or large fabrication projects, our tools guarantee clean and precise cuts.

Versatile Applications:

Designed to work with a variety of tube sizes and materials, our notching tools can handle multiple types of metal, including stainless steel, carbon steel, and aluminum.

Sheet Metal Notching Tool Capabilities:

In addition to tube notching, these tools can also be used as sheet metal notching tools, allowing you to create notches in flat metal sheets for applications like HVAC systems, automotive parts, and other industrial uses.

Adjustable Notching Angles:

Some models come with adjustable angle settings, enabling custom notches for different project needs, ensuring versatility and ease in complex fabrication processes.

Heavy-Duty Construction:

Built with durability in mind, our tube notching tools are designed to withstand high-volume operations, delivering long-lasting performance in commercial and industrial settings.

Safety and Manufacturing Considerations

Safety is critical when using notching tools. Our tube notching tools are designed with safety features such as automatic shutoff, secure clamps, and ergonomic handles to ensure operator safety during use.

Our rigorous quality control process ensures that each tool meets the highest standards for precision, safety, and performance. By choosing sheet metal notching tools from us, you’re investing in reliable equipment that will help your team achieve accurate, safe, and efficient fabrication results.

Technical Specifications - HIW Series

Punching Specifications

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Dia x Thickness) | 22 x 16 45 x 8 |

22 x 20 50 x 9 |

30 x 20 50 x 12 |

30 x 25 50 x 15 |

30 x 25 50 x 15 |

33 x 28 50 x 18 |

36 x 32 50 x 23 |

40 x 38 50 x 30 |

| Throat Depth (S / SD Model) | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/Min. (20mm Stroke) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to Die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

Flat Shearing Capacity

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Flate Bar Shear (Width x Thickness) | 300 x 12 240 x 16 |

350 x 15 240 x 20 |

460 x 15 300 x 20 |

610 x 16 400 x 20 |

610 x 16 400 x 20 |

610 x 18 400 x 25 |

760 x 20 400 x 30 |

700 x 25 425 x 30 |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle Flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

Angle Shearing Details

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

Section & Bar Shearing

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

Notching Specifications

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

Optional Tooling

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

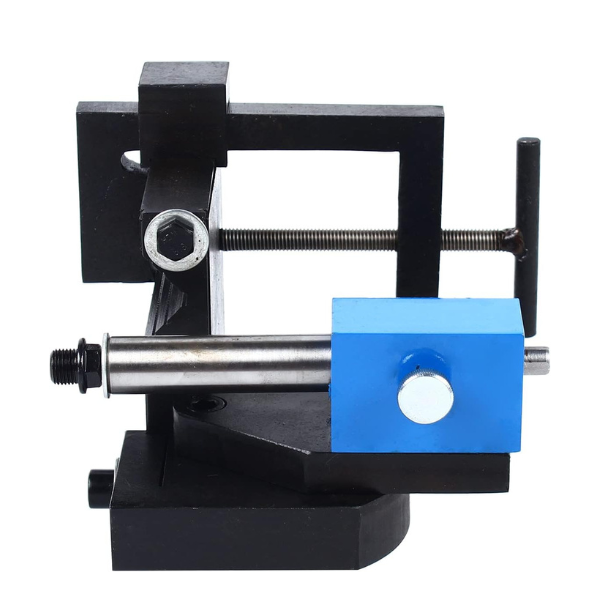

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

Other Specifications

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimensions (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Benefits of Using Tube Notching Tools

Utilizing a high-quality tube notching tool brings several advantages to your fabrication processes:

- Enhanced Accuracy: Achieve precise, clean cuts and notches that improve the overall quality of your work, especially when working with tubes and pipes for welding and structural purposes.

- Time and Cost Savings: Streamline your production by using efficient sheet metal notching tools that reduce material waste, lower labor costs, and shorten production times.

- Versatility in Metalworking: Our tools handle various materials and sizes, making them suitable for a range of projects, from small repairs to large-scale structural work.

- Improved Workflow: With their user-friendly design, these tools integrate seamlessly into your existing workflow, enhancing overall productivity and reducing manual labor.

- Long-Lasting Durability: Constructed from high-quality materials, our tube notching tools are built to last, ensuring reliable performance over time, even in demanding environments.

Built for Precision and Performance

Watch Our Toweline Machines in Action :

Based On Material Strength Of 450 N/MM2

Illustrations, Dimension & Weights Are Not Binding As Design Are Constantly Being Reviewed