CNC Punching and Drilling Machines

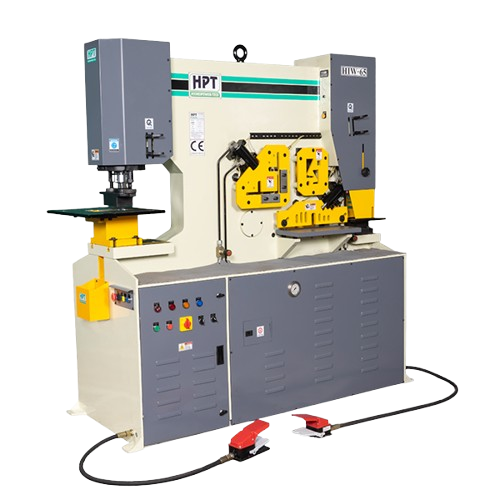

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer of CNC Punching and Machines

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Fabrication CNC Punching and Machines.

A CNC punching and drilling machine is an advanced solution for fabricators who need precise hole-making, stamping, and marking in structural steel. With high-speed, multi-axis functionality, it automates tasks such as punching bolt holes, drilling base plates, and engraving part IDs—ensuring accuracy and consistency across all projects.

- Automates punching, drilling, and marking with high accuracy and speed.

- Enhances throughput while reducing rework in structural steel fabrication.

Ideal for beam and plate manufacturing as well as heavy infrastructure, this machine boosts throughput, reduces rework, and ensures compliance with international fabrication standards—making it an essential tool for modern steel production facilities.

“Power. Precision. Performance – The HPT Ironworker Promise.”

CNC Punching and Drilling Machine Features

Precision Hole-Making

Whether processing base plates, flanges, or channel profiles, the structural steel hole-making line machine ensures perfectly aligned, clean holes every time—essential for bolted connections in towers and frames.

High-Speed Drilling

Built for performance, the high-speed steel drilling machine module features servo-driven spindles and automatic tool changers, enabling rapid drilling of thick steel sections without compromising accuracy.

Punching & Tapping

With hydraulic or electric punching heads, the CNC punching and drilling machine handles various hole shapes and sizes. Optional tapping units allow threaded holes to be created within the same setup.

Marking & Stamping

Integration with an automatic steel marking machine ensures each part is traceable during assembly and logistics. The CNC stamping and engraving system adds logos, batch codes, or component labels directly onto the surface.

3-Axis Control

Many models include a 3-axis CNC drilling line machine configuration, allowing for simultaneous drilling across flanges, webs, and sides—boosting efficiency for profiles like H-beams, angles, and plates.

Flexible Automation

Material loaders, discharge conveyors, and in-line tool calibration systems make this machine ideal for continuous production environments and batch processing with minimal downtime.

Safety and Manufacturing Considerations

The CNC punching and drilling machine is equipped with smart safety systems, including protective barriers, overload sensors, and emergency stops to ensure operator protection. Real-time diagnostics and integrated software control provide oversight on accuracy, machine health, and cycle optimization.

Manufacturers of high-speed steel drilling machines and automatic steel marking machines invest heavily in stable design, intelligent feedback systems, and rugged construction—ensuring the machine delivers under the most demanding workloads

Elevate Your Steel Fabrication with United Structural Works

Whether you’re producing structural components for bridges, high-rise buildings, or transmission towers, the CNC punching and drilling machine brings automation, accuracy, and efficiency to every hole and mark.

From the speed of the 3-axis CNC drilling line machine to the traceability offered by the CNC stamping and engraving system, this all-in-one unit elevates your production capabilities and eliminates bottlenecks in traditional workflows.

The CNC punching and drilling machine isn’t just a tool—it’s your frontline productivity engine for steel processing success.

Built for Precision and Performance

Watch Our CNC Channel Line Machines in Action :

Discover the strength, accuracy, and efficiency of our Hydraulic Punching Machines in action. Watch how our models deliver powerful, precise hole punching on thick and tough materials, ensuring reliability and consistency for industrial applications.