HPT, A Leading Manufacturer of CNC Channel Line Machines

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Fabrication Machinery Manufacturers.

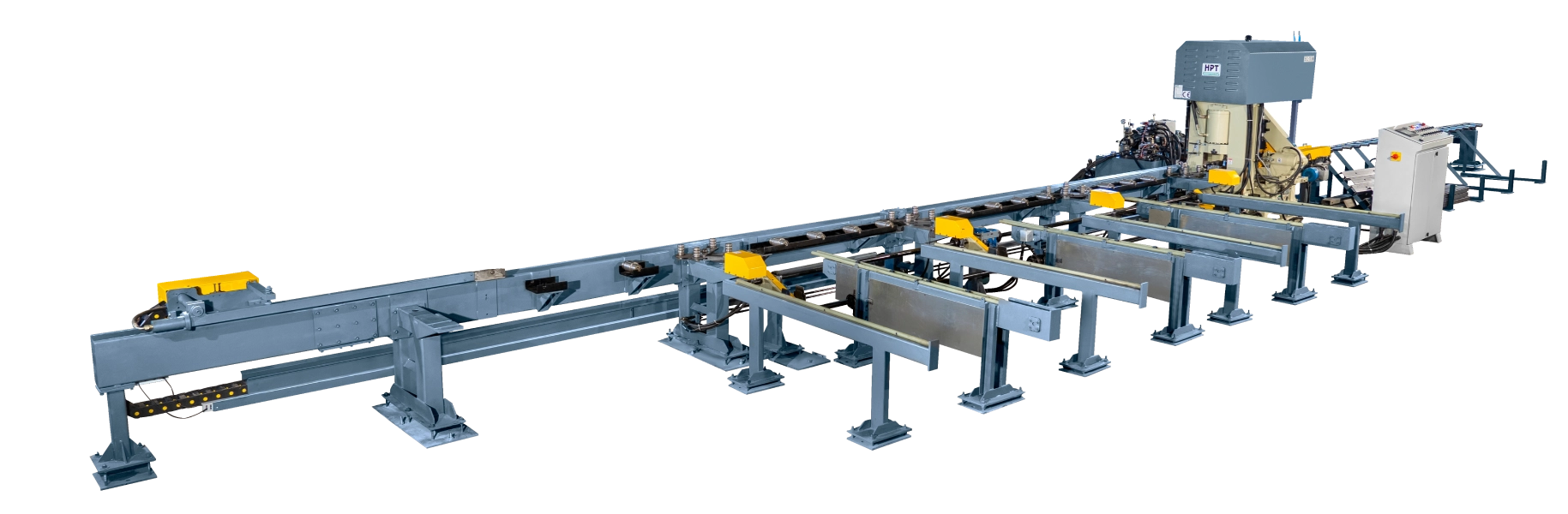

A CNC channel line machine is a vital asset for fabricators handling steel channels and flat bars. Designed for precision, it automates cutting, punching, and drilling, ensuring efficiency and accuracy in every operation. Widely used in construction, manufacturing, and structural steelwork, these machines can also process punched steel flat bars, making them indispensable in modern production facilities.

- Automates cutting, punching, and drilling of steel channels and flat bars.

- Enhances productivity with advanced automation and versatile functions.

Our steel worker and metal worker machines are built to maximize productivity while maintaining superior quality. With advanced automation and versatile functionality, they streamline steel channel processing, reduce manual effort, and deliver reliable performance across a range of fabrication tasks.

“Power. Precision. Performance – The HPT Ironworker Promise.”

CNC Channel Line Machines Features

Channel Accuracy

Auto Channel Feed

Integrated Operations

Heavy Rigidity

Channel Clamping

Production Speed

Safety and Manufacturing Considerations

Safety is a top priority when operating a steel worker machine. Our CNC channel line machines are designed with various safety features such as emergency stop buttons, safety shields, and automatic shutoff mechanisms to protect operators from potential hazards.

Our commitment to quality ensures that each machine undergoes rigorous testing before it reaches the production floor. We follow strict quality control measures to ensure reliability, efficiency, and durability, providing you with a machine that meets all safety and performance standards.

Benefits of Using CNC Channel Line Machines

- Increased Efficiency: Our steel worker machines are designed for speed and precision, reducing cycle times and increasing throughput, leading to improved productivity.

- Versatility Across Applications: Whether working with punched steel flat bars or steel channel processing machines, our equipment is capable of handling a wide range of metalworking tasks, from basic cuts to complex punching and drilling.

- Precision and Accuracy: Achieve consistent, high-quality results with every project. Our metal worker machines ensure accurate cuts, holes, and markings that meet your fabrication standards.

- Cost Reduction: By automating several manual tasks, our CNC channel line machines help reduce labor costs, minimize errors, and lower material waste, improving your bottom line.

- Long-Term Durability: Built with the highest quality components, these machines are designed to withstand continuous, high-volume operations, ensuring long-term reliability and minimal maintenance.

Technical Specifications - HC Series

| Model | HC7510 | HC7515 | HC1730 | |

|---|---|---|---|---|

| Functions | CNC C Channel Punching, Cutting & Marking Machines | |||

| C Channel Size min (mm) | 75 x 40 x 5 | 75 x 40 x 5 | 175 x 75 x 6 | |

| C Channel Size max (mm) | 100 x 50 x 5 | 150 x 75 x 6 | 300 x 90 x 8 | |

| No. of Character | 16 | |||

| Max. Punching Diameter (mm) | Ø32 | |||

| Punching force Web / Flange (kN) | 300 / 400 | 500 / 650 | ||

| No. of Tools | 2 + 1 / 2 + 2 | |||

| Marking Force (kN) | 1600 | |||

| Shearing force (kN) | 800 | 1000 | 1800 | |

| Models Available In Automatic & Semi – Automatic | ||||

Enhance Your Fabrication Process with Our CNC Channel Line Machines

Whether you’re using a CNC channel line machine for precise steel channel processing or a metal worker machine for various fabrication tasks, our equipment is designed to meet the demands of modern fabrication. By integrating these advanced machines into your workflow, you can streamline operations, reduce labor costs, and improve the quality of your products.

Invest in our high-performance machines and elevate your production capabilities today. With reliable, versatile, and efficient equipment, your business will benefit from increased productivity and reduced overhead costs.

Built for Precision and Performance

Watch Our CNC Channel Line Machines in Action:

Discover the strength, accuracy, and efficiency of our Hydraulic Punching Machines in action. Watch how our models deliver powerful, precise hole punching on thick and tough materials, ensuring reliability and consistency for industrial applications.