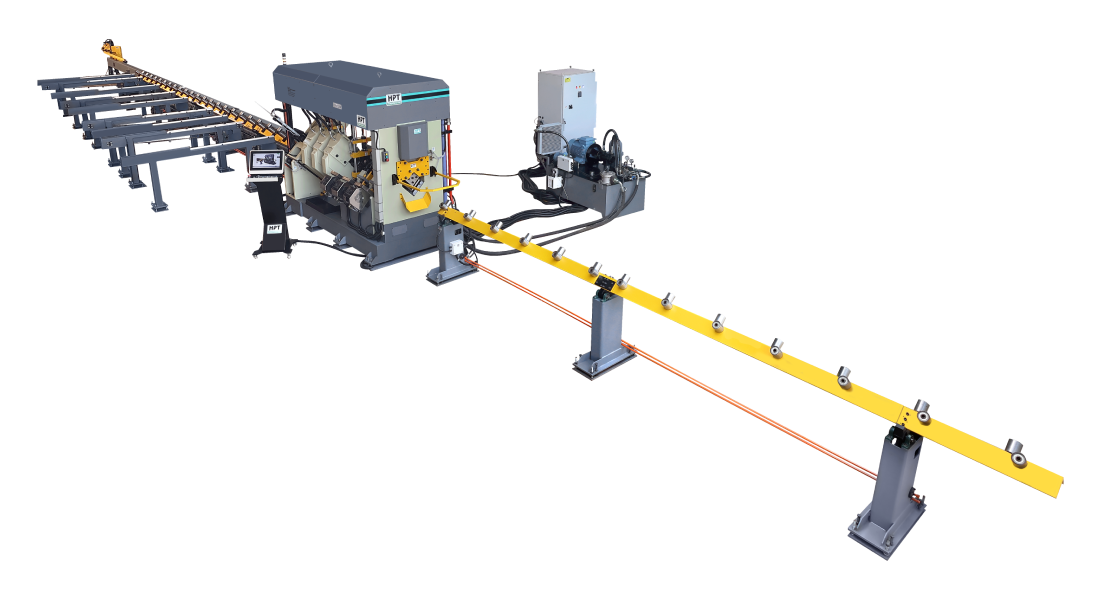

HPT, A Leading Manufacturer of CNC Angle Line Machines

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance CNC Angle Line Manufacturers.

- Delivers high-speed, precise drilling, punching, shearing, and marking of steel angles.

- Optimizes workflow while reducing labor costs in large-scale fabrication.

“Power. Precision. Performance – The HPT Promise.”

CNC Angle Line Machines Features

High Precision

Material Auto Feeding

Multi-Operation

Rigid Frame

Smart Software

Production Efficiency

Safety and Manufacturing Considerations

With the high-speed movement of components and intense power involved, safety is a top priority when operating a CNC angle line machine. Automated guarding, emergency stops, and remote monitoring features are standard in well-designed machines.

Manufacturers of CNC angle drilling line machines and CNC angle shearing machines emphasize precision engineering, stable base construction, and intelligent control systems. Meeting evolving industry demands requires CNC angle punching line machines that are both adaptable and efficient.

CNC Angle Line Machines: Power Meets Precision

These machines are built to handle the demanding needs of steel structure fabrication. Whether you’re processing 40×40 angles or large 200×200 sections, the CNC angle line machine simplifies what was once a multi-step, labor-heavy process.

From punching tower holes to drilling base plates and shearing structural components, each CNC angle line machine replaces multiple manual tasks with one streamlined, automated solution. The integration of CNC angle drilling line machine, punching, and shearing functions means faster production cycles and less room for human error.

When manufacturing transmission tower angle line machine components, precision and repeatability are non-negotiable. That’s why CNC angle shearing machines and angle punching systems are trusted by leading fabrication facilities worldwide.

With its unmatched efficiency, safety, and accuracy, a CNC angle line machine quickly becomes the backbone of any structural steel processing line—whether in tower fabrication, power infrastructure, or large-scale steel engineering.

Technical Specifications - HA Series

| Model | HA708 | HA1010 | HA1212 | HA1412 | HA1516 | HA2020 |

|---|---|---|---|---|---|---|

| Functions | CNC Angle Punching, Cutting & Marking Machines | |||||

| Angle Size min (mm) | 30 x 30 x 3 | 40 x 40 x 3 | 40 x 40 x 4 | 40 x 40 x 4 | 50 x 50 x 5 | 60 x 60 x 5 |

| Angle Size Max. (mm) | 70 x 70 x 8 | 100 x 100 x 10 | 120 x 120 x 12 | 140 x 140 x 12 | 150 x 150 x 16 | 200 x 200 x 20 |

| No. of Character | 16 | |||||

| Max. Punching Diameter (mm) | Ø32 | |||||

| Tools Per Flange | 2 | 3 | ||||

| Marking Force (kN) | 1600 | |||||

| Punching force (kN) | 500 | 600 | 700 | 700 | 900 | 1150 |

| Shearing force (kN) | 700 | 1200 | 1600 | 2000 | 2800 | 4500 |

| Material Grade | 550 N/mm2 (HT Grade) | |||||

| Models Available In Automatic & Semi – Automatic | ||||||

Built for Precision and Performance

Watch Our CNC Angle Line Machines in Action:

Discover the strength, accuracy, and efficiency of our Hydraulic Punching Machines in action. Watch how our models deliver powerful, precise hole punching on thick and tough materials, ensuring reliability and consistency for industrial applications.