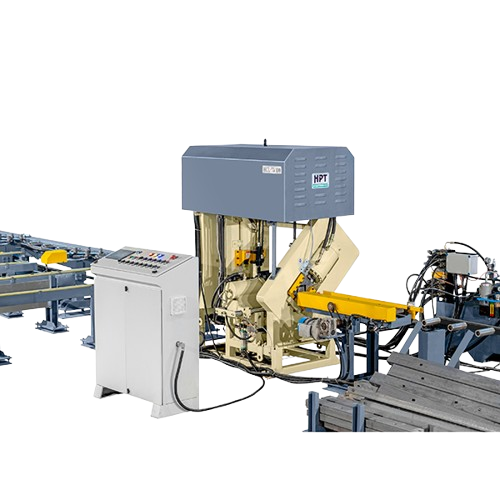

CNC Angle and Channel Line Machine

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer of CNC Angle and Channel line Machine

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance CNC Angle and CNC Channel Line Machines.

These machines are automatic special production line used for angle and channel marking, punching and shearing, mainly in the field of tower industry, electric power fittings, Agriculture Industries, structure storage facilities, and steel structure construction industries etc.

- High productive CNC Punching and Shearing Line for Angle And Channel

- CNC Machine for Angle Tower / Electric Fitting

Our commitment to engineering excellence and customer satisfaction makes HPT a trusted partner for businesses upgrading their metalworking efficiency.

“Power. Precision. Performance – The HPT Ironworker Promise.”

Complete Angle and Channel Processing Solutions

This range of lines therefore retains the prerogative of being flexible and adaptable to the customer’s requirements, thus being an affordable investment suitable also for small and mid-size companies.

The “HA & HC” lines are exceptional work cells where an angle enters as a stock length and exits as a finished part after the programmed combination of processes such as punching, drilling, marking and shearing. The customer can easily configure the line to address their specific needs:

- Versions with 1, 2 or 3 different punch diameters on each Side of the angle and channel.

- CNC programmable cartridge style marker.

- Automatic stock length loading tables

- Rotary loaders for the automatic transfer of angles from the loading table to the system infeed conveyor.

CNC Angle and CNC Channel Line Machine Features

CNC Punching Machines:

These machines ensure precise hole creation in metal sheets and plates using interchangeable dies. Automated CNC punching machines enhance speed and accuracy while reducing material waste.

Angle Cutting:

A CNC cutting machine delivers clean and precise cuts on metal angles, ensuring consistency in structural applications. These machines provide exceptional accuracy, making them ideal for large-scale metal processing.

Section and Bar Cutting:

High-performance CNC cutter machines efficiently cut through C Sections, I Sections, round and square bars, and rods, ensuring smooth and accurate material preparation.

Flat Shearing

A well-built CNC steel processing system provides seamless shearing of metal sheets and flat bars, enabling clean, straight cuts with minimal manual effort.

Notching

Precision-engineered CNC fabricators can execute intricate notching and cut-outs, making them essential for structural assembly and component manufacturing.

Bending and Customization:

Many Angle CNC machines India come with bending attachments to form metal plates, bars, and angles into precise shapes, allowing customization based on industrial requirements.

Safety and Manufacturing Considerations

Safety is critical when operating iron work machines due to their power and potential hazards. Proper operator training and strict adherence to safety protocols are essential for any ironworker machine for manufacturer facilities.

Leading ironworker machine manufacturers focus on precision engineering, robust fabrication, and rigorous quality control to ensure reliability and efficiency. Understanding market demands, competition, and customer requirements is crucial for producing high-performance iron worker machines that meet industry standards.

Technical Specifications -

CNC Angle Line Machines

| Model | HA708 | HA1010 | HA1212 | HA1412 | HA1516 | HA2020 |

|---|---|---|---|---|---|---|

| Functions | CNC Angle Punching, Cutting & Marking Machines | |||||

| Angle Size min (mm) | 30 x 30 x 3 | 40 x 40 x 3 | 40 x 40 x 4 | 40 x 40 x 4 | 50 x 50 x 5 | 60 x 60 x 5 |

| Angle Size Max. (mm) | 70 x 70 x 8 | 100 x 100 x 10 | 120 x 120 x 12 | 140 x 140 x 12 | 150 x 150 x 16 | 200 x 200 x 20 |

| No. of Character | 16 | |||||

| Max. Punching Diameter (mm) | Ø32 | |||||

| Tools Per Flange | 2 | 3 | ||||

| Marking Force (kN) | 1600 | |||||

| Punching force (kN) | 500 | 600 | 700 | 700 | 900 | 1150 |

| Shearing force (kN) | 700 | 1200 | 1600 | 2000 | 2800 | 4500 |

| Material Grade | 550 N/mm2 (HT Grade) | |||||

| Models Available In Automatic & Semi – Automatic | ||||||

CNC Channel Line Machine

| Model | HC7510 | HC7515 | HC1730 | |

|---|---|---|---|---|

| Functions | CNC C Channel Punching, Cutting & Marking Machines | |||

| C Channel Size min (mm) | 75 x 40 x 5 | 75 x 40 x 5 | 175 x 75 x 6 | |

| C Channel Size max (mm) | 100 x 50 x 5 | 150 x 75 x 6 | 300 x 90 x 8 | |

| No. of Character | 16 | |||

| Max. Punching Diameter (mm) | Ø32 | |||

| Punching force Web / Flange (kN) | 300 / 400 | 500 / 650 | ||

| No. of Tools | 2 + 1 / 2 + 2 | 500 / 650 | ||

| Marking Force (kN) | 1600 | |||

| Shearing force (kN) | 800 | 1000 | 1800 | |

| Models Available In Automatic & Semi – Automatic | ||||

Advanced CNC Angle and Channel Line Machines for Efficient Metal Processing

A CNC Angle and Channel Line Machine combines multiple metal fabrication functions into one efficient system, optimizing space and maximizing productivity for fabricators of all sizes.

Need precise holes in steel plates? A CNC punching machine gets the job done effortlessly. Cutting angles for structural frames? The CNC cutting machine ensures clean, accurate cuts. From processing C and I sections to shaping round and square bars, these machines handle tough metalworking tasks with speed and precision.

What sets these machines apart isn’t just their cutting capabilities. Many CNC fabricators include advanced notching stations for accurate cutouts and bending attachments for forming metal to exact specifications. This versatility makes a CNC machine for steel a must-have for streamlined operations and faster project completion.

Safety is a top priority when working with high-powered CNC steel machines. Proper training is essential, and top manufacturers integrate advanced safety features while maintaining the precision and reliability required for professional metal fabrication.

From small workshops to large manufacturing plants, a high-quality CNC angle and channel line machine is the key to efficient, high-speed metal processing.

Built for Precision and Performance

Watch Our Toweline Machines in Action :

Based On Material Strength Of 450 N/MM2

Illustrations, Dimension & Weights Are Not Binding As Design Are Constantly Being Reviewed