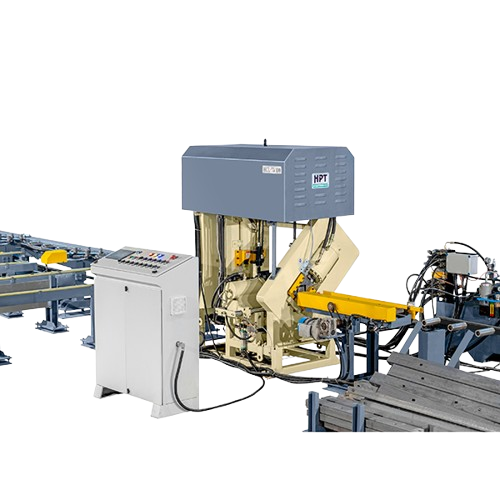

Plate Processing Machine

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer of Plate Processing Machine

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Plate Processing Machine.

A plate processing machine is a high-precision system built to automate punching, drilling, marking, shearing, and cutting on steel plates. From substation foundations to lattice tower CNC punching line fabrication, it streamlines essential production processes for the steel structure industry.

- Automates punching, drilling, shearing, and cutting of steel plates with precision.

- Handles large-format plates efficiently, ensuring speed and repeatability.

Designed to manage thick and large-format plates with minimal error, this machine is a must-have for transmission tower manufacturers, heavy-duty fabricators, and large infrastructure projects where speed, accuracy, and repeatability are critical.

“Power. Precision. Performance – The HPT Ironworker Promise.”

Safety and Manufacturing Standards

Given the high force and speed involved in plate processing, safety is built into every component. Emergency stops, protective barriers, and automatic alignment reduce operator risks while maintaining production speed.

Reputable manufacturers of CNC plate punching machines, CNC drilling machines, and hydraulic plate shearing machines focus on rugged machine frames, precision engineering, and smart software for industry-compliant results.

Plate Processing Machine Features

Punching and Drilling

Equipped with servo-controlled heads, the CNC plate punching machine and CNC drilling machine modules allow fast, accurate hole creation across a wide range of steel plate thicknesses—perfect for tower base and anchor plate manufacturing.

Shearing

The hydraulic plate shearing machine delivers clean, burr-free cuts on heavy steel plates. It reduces post-processing work and maintains edge precision, even for high-strength materials.

Stamping and Marking

With a plate marking and stamping machine, alphanumeric identifiers or assembly codes can be marked directly onto the plate surface, aiding in traceability and error-free assembly.

Tower Base Processing

The plate drilling line for tower base is a specialized configuration that supports high-speed, high-volume hole drilling for foundation and base plate fabrication in transmission tower and utility infrastructure projects.

Thermal Cutting

For additional flexibility, integration with a CNC flame/plasma cutting machine allows for detailed contour cuts, custom profiles, and edge finishing—all in one station.

Automation & Customization

A complete steel plate fabrication system includes automatic plate feeding, clamping, and discharge modules—boosting efficiency and minimizing human error across the entire process.

Plate Processing Machines: Engineered for Tower-Grade Performance

From tower base plates to lattice supports, the plate processing machine delivers the strength, flexibility, and precision modern fabrication demands. Whether you’re running a lattice tower CNC punching line or a mixed plate cutting system, automation ensures fewer errors and faster project delivery.

The combination of a CNC drilling machine and CNC plate punching machine offers unmatched versatility for heavy fabrication, while the hydraulic plate shearing machine ensures edge perfection at scale.

With rising infrastructure demands and tighter production deadlines, the plate processing machine becomes your frontline tool for competitive steel fabrication—driving results where it matters most.

Built for Precision and Performance

Watch Plate Processing Machines in Action :

Based On Material Strength Of 450 N/MM2

Illustrations, Dimension & Weights Are Not Binding As Design Are Constantly Being Reviewed