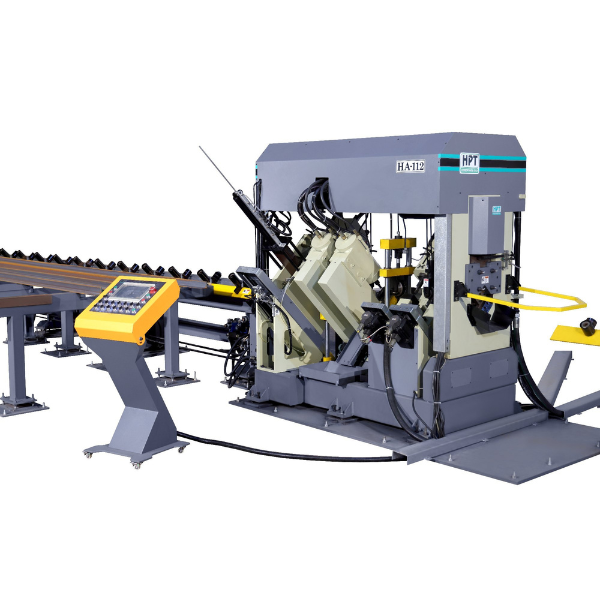

CNC Beam Line Machine

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer of CNC Channel Line Machines

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance CNC Beam Line Machine.

A CNC beam line machine is a high-performance solution designed to automate the drilling, cutting, and marking of steel beams with exceptional accuracy. Essential for large-scale construction, industrial frameworks, and transmission tower fabrication, it ensures efficient and precise steel structure production.

- Automates drilling, cutting, and marking of steel beams with high precision.

- Enhances productivity with advanced automation and versatile functions.

Capable of handling H-beams, I-beams, and box sections, a robust CNC beam line machine reduces manual labor and boosts productivity. Its automated system streamlines workflows, minimizes material waste, and guarantees precise fabrication of each component.

“Power. Precision. Performance – The HPT Ironworker Promise.”

CNC Channel Line Machines Features

Drilling & Punching

Whether you’re processing H-beams or I-beams, the CNC H beam drilling line machine delivers fast, accurate hole drilling across multiple faces in one pass. Some systems also support high-speed punching for light-gauge profiles.

I-Beam Processing

The integrated CNC I-beam processing machine ensures simultaneous web and flange drilling, along with marking or tapping operations—all in a single setup. It’s ideal for fabricating load-bearing structures and support columns.

Beam Feeding & Positioning

Equipped with automatic feeding rollers and positioning sensors, the CNC beam line machine handles long beams with minimal supervision. This enhances efficiency in any structural steel beam line machine setup.

Cutting and Sawing

Many models offer integration with an automatic beam cutting machine, which delivers precise miter cuts and straight sawing to meet structural design requirements.

Customization

From transmission tower parts to complex industrial frames, the CNC beam line machine can be adapted to suit specific production needs in both mid- and large-scale operations.

Safety and Manufacturing Considerations

Operating a CNC H beam drilling line machine or a CNC I-beam processing machine involves handling heavy materials and high-speed tools. That’s why modern beam line systems come with robust safety features, including enclosed cutting zones, laser alignment, emergency stop controls, and user-friendly interfaces.

Top manufacturers of structural steel beam line machines focus on build quality, software integration, and post-sale service to ensure long-term performance in demanding environments. These machines are designed not just for capacity—but for absolute precision and safety.

Benefits of Using CNC Beam Line Machines: Built for Big Jobs, Trusted for Precision

When you’re fabricating steel beams for industrial sheds, warehouses, bridges, or transmission tower fabrication machines, precision isn’t optional—it’s essential. A CNC beam line machine replaces outdated, manual methods with an intelligent, computer-controlled workflow.

From beam marking to drilling to cutting, every step is streamlined. Whether you’re running a CNC H beam drilling line machine for vertical construction or a CNC I-beam processing machine for horizontal load-bearing structures, the result is the same: high-speed, low-error, cost-efficient production.

For any steel fabricator serious about scaling up, the CNC beam line machine quickly becomes the centerpiece of structural manufacturing—saving time, labor, and money while delivering consistent, project-ready results.

Built for Precision and Performance

Watch Our CNC Channel Line Machines in Action :

Discover the strength, accuracy, and efficiency of our Hydraulic Punching Machines in action. Watch how our models deliver powerful, precise hole punching on thick and tough materials, ensuring reliability and consistency for industrial applications.