Hydraulic Notching Machines

Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer Notching Machine

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Hydraulic Notching Machines.

A hydraulic notching machine is a powerful and versatile tool designed to cut, notch, and shape metal materials with precision and efficiency. Widely used in construction, metal fabrication, and manufacturing, it offers durability and the ability to handle demanding heavy-duty tasks.

- Increases efficiency and reduces manual labor in fabrication.

- Provides precise solutions for angular, pipe, and sheet metal notching.

Partnering with a reliable hydraulic notching machine manufacturer ensures long-term performance and productivity. From angular notching to pipe and sheet metal applications, these machines enhance efficiency, reduce manual labor, and streamline fabrication, making them an essential investment for any workshop or facility.

“Power. Precision. Performance – The HPT Ironworker Promise.”

Hydraulic Notching Machine Features

Precision Punching:

Creates accurate holes of different sizes and shapes in metal sheets using interchangeable punch dies. A hydraulic notching machine manufacturer ensures superior punching capabilities.

Efficient Angular Notching:

A hydraulic angular notching machine provides clean, precise cuts for angular profiles, making it indispensable for fabrication and structural work.

Pipe Notching Accuracy:

A hydraulic pipe notching machine enables precise notching in pipes, ensuring smooth assembly in welding and industrial applications.

Flat Metal Shearing:

Delivers straight, smooth cuts on metal sheets and flat bars with minimal effort, improving workflow efficiency.

Specialized Notching Features:

A sheet metal notching tool ensures accurate cut-outs and notches, essential for complex structural applications.

Bending and Forming Capabilities:

Some hydraulic notching machines come with bending attachments, allowing for customized metal shaping.

Customizable Solutions:

Available in various models, hydraulic notching machines are designed to meet different industry-specific fabrication requirements.

Safety and Manufacturing Considerations

Operating a hydraulic notching machine requires strict safety adherence due to its high-powered mechanisms. Proper training and following safety guidelines are crucial for workplace safety.

Leading hydraulic notching machine manufacturers focus on precision engineering, durability, and strict quality control to deliver reliable, high-performance sheet metal notching tools and hydraulic pipe notching machines that meet modern fabrication demands.

Technical Specifications - HIW Series

Punching Specifications

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Dia x Thickness) | 22 x 16 45 x 8 |

22 x 20 50 x 9 |

30 x 20 50 x 12 |

30 x 25 50 x 15 |

30 x 25 50 x 15 |

33 x 28 50 x 18 |

36 x 32 50 x 23 |

40 x 38 50 x 30 |

| Throat Depth (S / SD Model) | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/Min. (20mm Stroke) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to Die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

Flat Shearing Capacity

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Flate Bar Shear (Width x Thickness) | 300 x 12 240 x 16 |

350 x 15 240 x 20 |

460 x 15 300 x 20 |

610 x 16 400 x 20 |

610 x 16 400 x 20 |

610 x 18 400 x 25 |

760 x 20 400 x 30 |

700 x 25 425 x 30 |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle Flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

Angle Shearing Details

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

Section & Bar Shearing

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

Notching Specifications

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

Optional Tooling

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

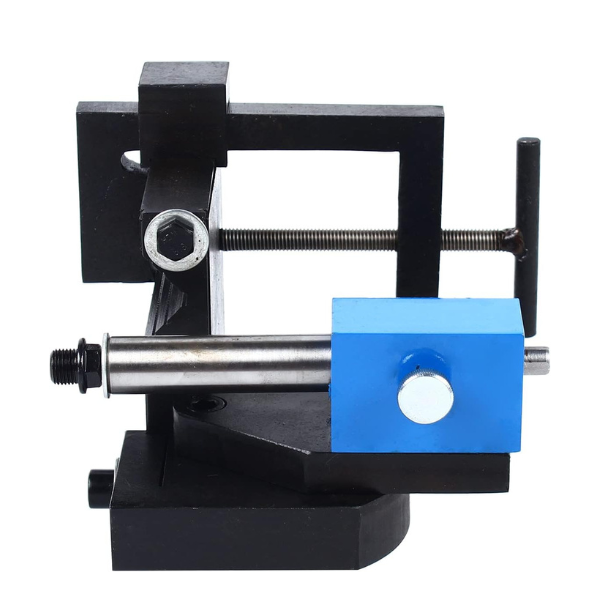

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

Other Specifications

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimensions (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Enhance Metal Fabrication with Advanced Hydraulic Notching Machines

These high-performance machines integrate multiple metalworking functions into a compact, durable design, optimizing space and enhancing productivity for fabricators of all sizes.

Need precise notches in metal sheets? A hydraulic notching machine delivers accuracy with ease. Cutting angles for structural applications? A hydraulic angular notching machine ensures clean, precise cuts. From shearing metal sheets to notching pipes, these machines handle tasks that would otherwise require multiple specialized tools.

Beyond cutting capabilities, these machines offer additional functions. Many hydraulic notching machines include dedicated notching stations for creating complex cutouts, while others feature bending attachments for shaping metal to exact specifications. For any hydraulic notching machine manufacturer, this versatility enhances production efficiency and expands fabrication capabilities.

With great power comes a strong focus on safety. These machines exert immense force, making operator training essential. Leading hydraulic notching machine manufacturers prioritize safety features while maintaining precision engineering to ensure clean and accurate results every time.

From small workshops to large-scale manufacturing plants, a well-built hydraulic pipe notching machine or sheet metal notching tool becomes a cornerstone of efficient metal fabrication operations.

Built for Precision and Performance

Watch Our Hydraulic Notching Machines in Action :

Based On Material Strength Of 450 N/MM2

Illustrations, Dimension & Weights Are Not Binding As Design Are Constantly Being Reviewed