Strong. Reliable. Built by HPT.

HPT, A Leading Manufacturer of Hydraulic Ironworker Machines

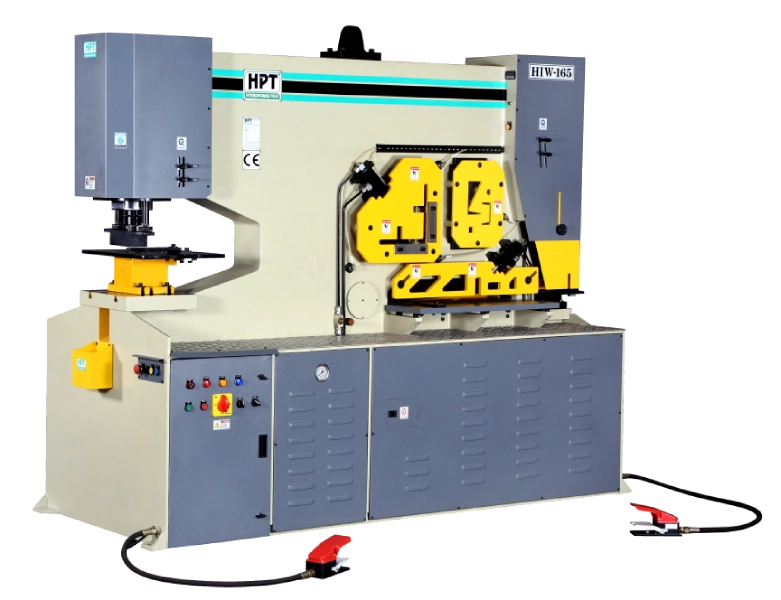

Hydro Power-Tech Engineering (HPT), based in Gujarat, India, has built a strong reputation for delivering high-performance Hydraulic Ironworker Machines (HIW-55 to HIW-220).

Designed for power, accuracy, and durability, our machines efficiently perform punching, shearing, bending, and notching operations. They are the preferred choice for industries like construction, shipbuilding, steel fabrication, and heavy manufacturing.

- Multi-purpose operations: Punching, Flat Shearing, Angle Cutting, Section & Bar Cutting, Notching, Bending

- Robust design with advanced hydraulics and easy-to-use controls

- Globally trusted for precision, reliability, and safety

Our commitment to engineering excellence and customer satisfaction makes HPT a trusted partner for businesses upgrading their metalworking efficiency.

“Power. Precision. Performance – The HPT Ironworker Promise.”

Ironworker Machine Features

Punching

Punch holes of various sizes & shapes in sheets and plates with interchangeable dies.

Angle Cutting

Dedicated angle-cutting station for precise cutting of angles & profiles.

Section & Bar Cutting

Easily cut C-section, I-section, round bars, square bars & rods with specialized tools.

Flat Shearing

Perform straight and clean cuts on metal sheets & flat bars using high-quality shear blades.

Notching

Create accurate notches & cutouts, ideal for assembly and component fabrication.

Bending

Bend plates, bars & angles into desired shapes with specialized bending attachments.

Customization Options

Models from HIW-55 to HIW-220 available to meet different production requirements.

Operator Safety

Designed with built-in safety measures & user-friendly controls to ensure safe operation.

Reliable Manufacturing

Engineered with robust fabrication & strict quality control for long-lasting performance.

Safety and Manufacturing Considerations

Safety is critical when operating iron work machines due to their power and potential hazards. Proper operator training and strict adherence to safety protocols are essential for any ironworker machine for manufacturer facilities.

Leading ironworker machine manufacturers focus on precision engineering, robust fabrication, and rigorous quality control to ensure reliability and efficiency. Understanding market demands, competition, and customer requirements is crucial for producing high-performance iron worker machines that meet industry standards.

Technical Specifications - HIW Series

Punching Specifications

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Dia x Thickness) | 22 x 16 45 x 8 |

22 x 20 50 x 9 |

30 x 20 50 x 12 |

30 x 25 50 x 15 |

30 x 25 50 x 15 |

33 x 28 50 x 18 |

36 x 32 50 x 23 |

40 x 38 50 x 30 |

| Throat Depth (S / SD Model) | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/Min. (20mm Stroke) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to Die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

Flat Shearing Capacity

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Flate Bar Shear (Width x Thickness) | 300 x 12 240 x 16 |

350 x 15 240 x 20 |

460 x 15 300 x 20 |

610 x 16 400 x 20 |

610 x 16 400 x 20 |

610 x 18 400 x 25 |

760 x 20 400 x 30 |

700 x 25 425 x 30 |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle Flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

Angle Shearing Details

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

Section & Bar Shearing

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

Notching Specifications

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

Optional Tooling

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

Other Specifications

| Particular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

|---|---|---|---|---|---|---|---|---|

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimensions (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Essential Functions and Advantages of a Hydraulic Ironworker Machine

- Precision Hole Punching: A hydraulic punching machine for sheet metal enables the accurate creation of holes in metal sheets and plates using interchangeable punch dies, ensuring consistency in fabrication.

- Accurate Angle Cutting: The hydraulic ironworker delivers clean and precise cuts for structural angles and custom profiles, making it ideal for construction and metalworking applications.

- Efficient Section and Bar Cutting: Equipped with specialized cutting tools, the hydraulic punch press machine seamlessly cuts through C Sections, I Sections, round and square bars, and rod stock, ensuring smooth workflow in fabrication shops.

- Seamless Flat Shearing: With minimal effort, the hydraulic ironworker machine provides smooth and straight cuts on metal sheets and flat bars, optimizing material usage and reducing waste.

- Advanced Notching Capabilities: Hydraulic punching machines efficiently create notches and cut-outs in metal components, streamlining structural assembly and fabrication processes.

- Metal Bending Solutions: Certain hydraulic ironworker models feature bending attachments that allow for the precise formation of metal bars, plates, and angles into custom shapes.

- Customizable for Specific Needs: Different hydraulic ironworker machine models offer a range of capabilities, allowing businesses to choose the right machine to meet their specific metal fabrication requirements.

Hydraulic Ironworker Machines: The Ultimate Metal Fabrication Solution

Hydraulic ironworker machines are essential tools for modern metal fabrication, combining multiple metalworking functions into a single, space-saving unit. These machines improve efficiency by handling a wide range of tasks, making them ideal for both small fabrication shops and large-scale manufacturing facilities.

Need precise hole punching in steel sheets? A hydraulic punching machine for sheet metal ensures clean and accurate results. Cutting angles for structural frames? A hydraulic ironworker delivers sharp, precise cuts with minimal effort. From slicing through C and I sections to shaping round and square bars, these machines eliminate the need for multiple specialized tools, streamlining the fabrication process.

But cutting and punching aren’t the only strengths of these machines. Many hydraulic ironworkers also include hydraulic punch press machine stations for precision cutouts and notching, as well as bending attachments for forming metal to exact specifications. This versatility helps manufacturers enhance productivity, reduce manual labor, and expand their fabrication capabilities.

Safety is a critical factor when operating high-powered hydraulic punching machines. These machines exert immense force, making operator training essential. Leading manufacturers design hydraulic ironworker machines with advanced safety features while ensuring precise, high-quality performance for every task.

From repair workshops to industrial manufacturing plants, a hydraulic ironworker machine is the backbone of efficient, high-performance metal fabrication. Investing in the right machine guarantees durability, precision, and long-term cost savings for any fabrication business.

Built for Precision and Performance

Watch Our Hydraulic Ironworker Machines in Action :

Discover the power, precision, and versatility of our Hydraulic Ironworker Machines through our live demonstration video. Watch how our HIW-55 to HIW-220 models handle punching, shearing, and bending operations seamlessly.